|

|

|

|

Ron Clarke Horns

02_june_14

Ron Clarke has

brought us some of the very best modern Horn designs for Fostex drivers -- the Dallas

II for the FE206e, the Austin A166 for FE166e (seen here with FE168eSigma), &

the Austin A126e for the FE126e as well as having a hand in the development of the

Frugel-Horn.

Ron's Horns have brought the concepts of the curved mouth, the deflector, and the

supraBaffle to the fore. All 3 of these have been tied together in the Austin Horns.

There is more information on what these features bring in the Frugel-Horn documentation.

Ron uses some very sophisticated tools (see Ron's comments below) that allow him

the visualize the airflow in the horn. This, and an open-source model that encourages

user feedback has engendered a line of finely tuned horns -- none of them a rectangular

box. |

|

|

|

|

|

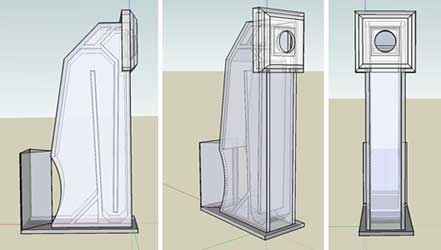

Austin

A126 (with non-standard supraBaffle) & 2 examples of Austin A166

|

|

|

|

|

|

Insides

of a Dallas II & Austin A166. The last 2 pictures of executions using smooth

curves, the Dallas in kerfcore, and the Austin "layertoned" (ie made of

a stack of CNCed MDF)

|

| |

|

|

| |

Actually i have never

built one outside of a test horn that was used to accumulate data and it wasn't the

Dallas II, but a step up from the original Dallas.

Neither have i built or heard the A126 or the Austin 166. All my designs are computer

simulated from a program that has undergone continuous change for over 2 years.

When i first got into Single Driver Full Range Back Loaded Horns (SD FR BLHs) i built

around 10 different horns all based on the figures established by the greybeards,

and even some from GM, and later i borrowed some of the math from Martin for the

TL action. During these builds i went thru extensive testing using pressure sensors

mounted inside the horns and established a great deal of data. Later i incorporated

a basic program which was established to measure pressure surges in petro chemical

vessels. This program was extensively modified to act with the data i had accumulated

and the different medium that the wave travelled thru. The program is still being

changed and if it will ever reach an end, i have no idea. The last major change came

about when Dave (planet 10) and Chris remarked on the compressed sound effect of

the A126. I thought the programming was correct, but when i investigated further

i realized there was an error in the BW of the horn vrs the baffle step. The answer

is an increased CC and the supra baffle.

All went to show me that i wasn't as smart as my boss thinks (if ya cant stun them

with brilliance, buffalo them with BS is my motto). Now i really have poor programming

skills, but a fair handle on math and some physics, so i have a young kid who is

an exceptional programmer actually do the work and all i do is say " incorporate

this or change that" and he really does the work, not me.

ron

I would highly recommend baltic birch over MDF for any Full Range design.

YES! After undergoing a fight for my life for the big C in my lungs i would go with

BB ply as MDF dust is just plain old bad for living things. Besides it takes weeks

to clean up those fine particles that gets into everything. |

|

| |

|

|

|

Plan Documents

|

|

Horn

|

|

Description |

|

|

Austin A126

|

|

Fostex FE126e |

|

Austin A166

|

|

Fostex FE166e |

|

Dallas II

|

|

Fostex FE206e |

|

Ed Horn Deflector

|

|

Add-on Deflector for the

Hornshoppe

Horn / 15-april-08 |

Note: these are plan documents

assembled from various bits & pieces that were gathered from various places on

the web. I will be working with Ron to get prettier, more consistent (& up-to-date

in some cases) drawings |

|